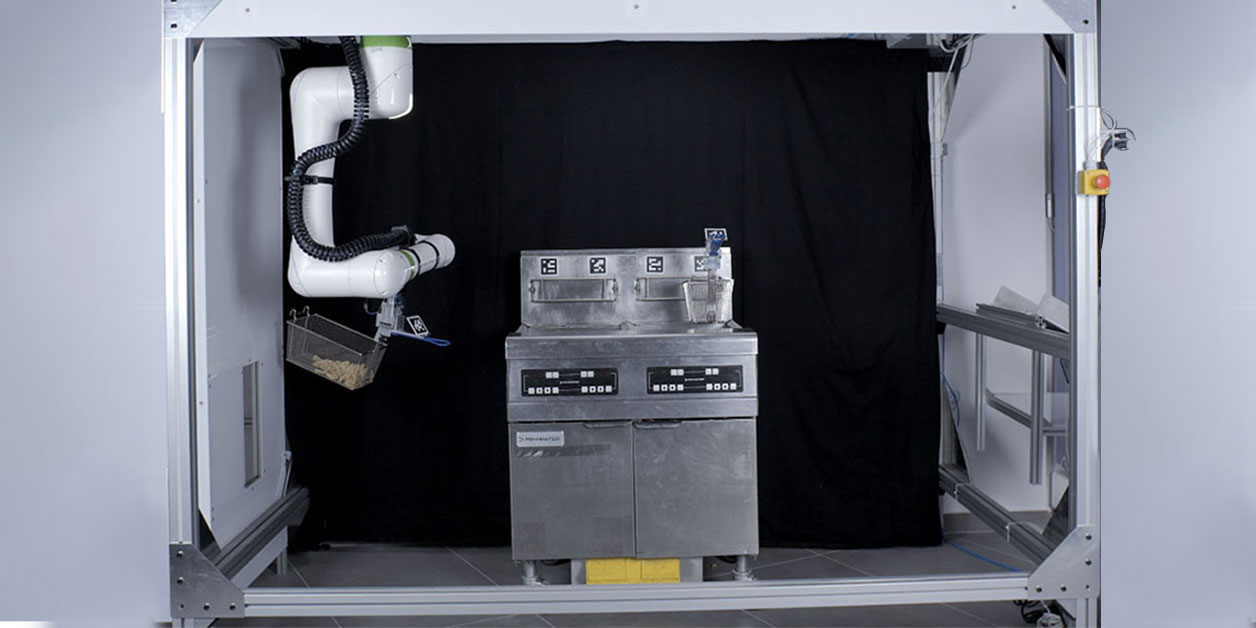

RoboFryer

Relying on ARUCO codes and 3D Depth AI camera with ML vision, the robotic hand knows where the fryer basket is, and simultaneously puts the filled basket in the oil and the other basket moves to the delivery funnel as a finished product.

Increased efficiency

RoboFryer is fast and can handle large volumes of food. Designed to replace human workers in tedious, repeatable QSR jobs to reduce waiting time and operational costs and to increase production output. Our team of robotics engineers designed a robotic cell for the robot to move from the depository cage filled with preprocessed food, to the fryer and up to the delivery funnel.

Improved food quality

With an automated system, the food is cooked at a precise temperature and time, resulting in better texture, flavor, and color.

Cost savings

Using a robot as a replacement for a worker in a kitchen fryer system can significantly reduce labor costs. The products can differ based on the food size product you can choose on the control panel attached to the robotic cell.

Increased safety

The automated system’s design includes multiple safety features such as built-in sensors, automatic shutoff, and emergency stop buttons to ensure safe operation.

Safe interaction

Collaborative robots are designed to work safely alongside humans, reducing the risk of accidents and injuries in the kitchen.

Automation in Intralogistics

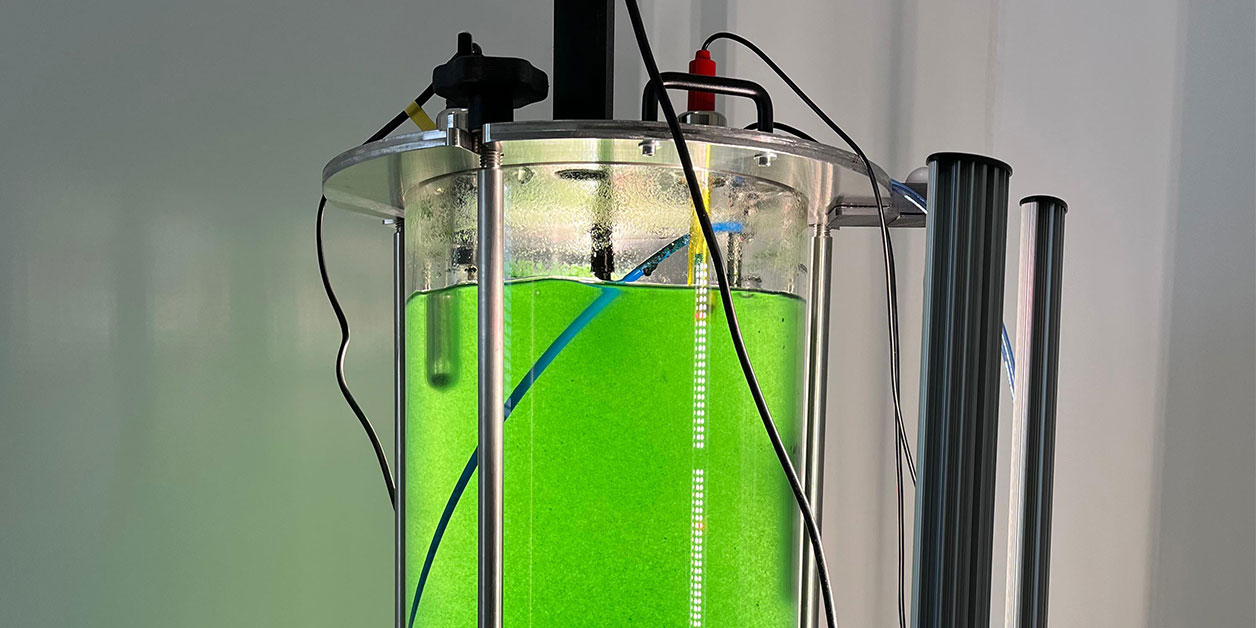

FBR-25L

Orox Spindle

Bottleneck Detector

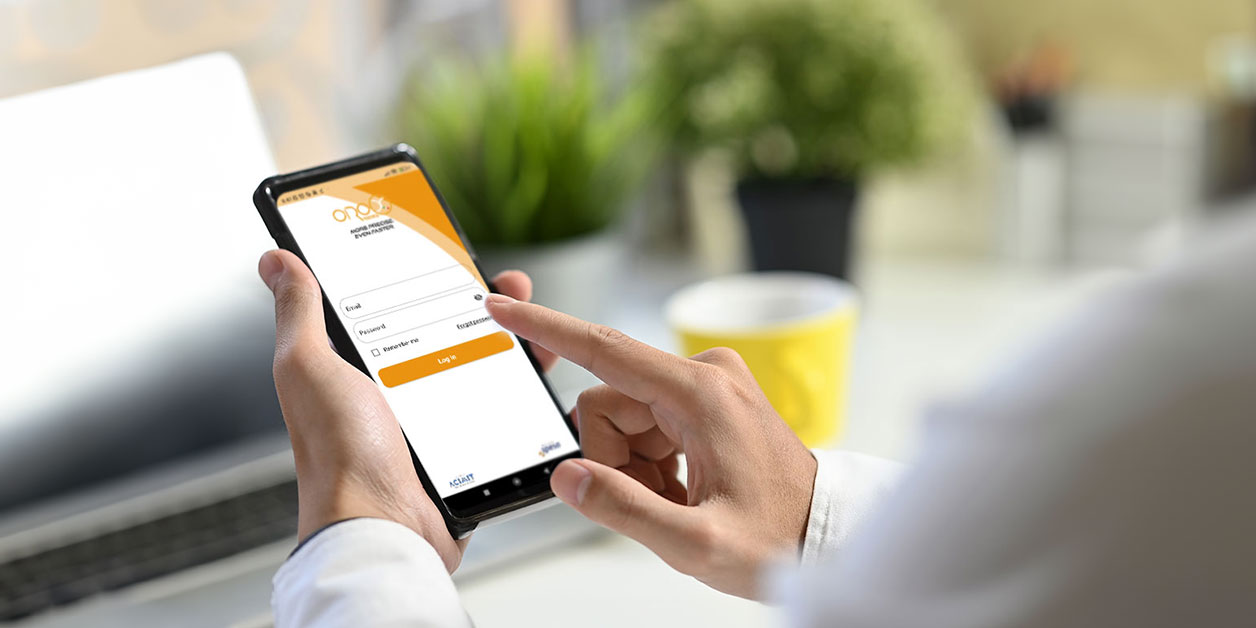

LyraScan